corrosion protection

Why corrosion?

Large-scale steel structure, lightning rod Tower, offshore lighthouse, large reservoir gate, water tower, offshore drilling facilities, tankers, and carbide spherical tanks, storage tanks, fuel tanks, towers, heat exchangers, chimneys, container, ship hulls, offshore steel structures, are constantly under marine atmosphere, atmospheric corrosion industrial environment. To long-term use, but not on a large scale maintenance, long-lasting protective coatings are best before, 20-30 years of life, lower maintenance costs, can obtain significant economic benefit.

Corrosion features atmosphere environment Xia of steel by Sun, and sand, and snow, and cream dew and the throughout the of temperature and humidity changes role, which atmosphere in the of oxygen and water is caused outdoor steel structure corrosion of important factors, caused steel corrosion of industrial gas contains SO2, and CO2, and NO2, and CI2, and H2S and the NH3,, these ingredients although content is small, but on steel of corrosion against are is not ignored of, which SO2 effect maximum, CI2 can makes metal surface passivation film was damage. The gas dissolves in the water is acidic, causing acid rain corrodes metal facilities.

Characteristics of ocean-atmosphere that contain a lot of salt, mainly NaCI, grains of salt deposition on the metal surface, because it has moisture and increase the surface electrical conductivity of liquid film effect CI-itself also has a strong corrosive, which will then increase the corrosion of metal surfaces. Steel corrosion off the coast near the more severe the corrosion rate is many times higher than in inland in the atmosphere.

Protection method:

Protection method:

Increased corrosion Coatings constitute a long-lasting corrosion protection of steel structures, or use heavy anticorrosive paint coating protection. Zinc and aluminum has a lot of characteristics of atmospheric corrosion resistance. In the zinc coating on the steel or aluminum, zinc, aluminum is negative and sacrificial anodes protection role in the formation of steel to make steel have been protected. Now coated with aluminum to prevent corrosion of industrial atmosphere, Ocean, atmosphere, and its features are as follows:

Spraying aluminum coating and steel substrate adhesion, coating firmly long life, good long-term economic benefitsCorrosion features atmosphere environment Xia of steel by Sun, and sand, and snow, and cream dew and the throughout the of temperature and humidity changes role, which atmosphere in the of oxygen and water is caused outdoor steel structure corrosion of important factors, caused steel corrosion of industrial gas contains SO2, and CO2, and NO2, and CI2, and H2S and the NH3,, these ingredients although content is small, but on steel of corrosion against are is not ignored of, which SO2 effect maximum, CI2 can makes metal surface passivation film was damage. The gas dissolves in the water is acidic, causing acid rain corrodes metal facilities.

Characteristics of ocean-atmosphere that contain a lot of salt, mainly NaCI, grains of salt deposition on the metal surface, because it has moisture and increase the surface electrical conductivity of liquid film effect CI-itself also has a strong corrosive, which will then increase the corrosion of metal surfaces. Steel corrosion off the coast near the more severe the corrosion rate is many times higher than in inland in the atmosphere.

Increased corrosion Coatings constitute a long-lasting corrosion protection of steel structures, or use heavy anticorrosive paint coating protection. Zinc and aluminum has a lot of characteristics of atmospheric corrosion resistance. In the zinc coating on the steel or aluminum, zinc, aluminum is negative and sacrificial anodes protection role in the formation of steel to make steel have been protected. Now coated with aluminum to prevent corrosion of industrial atmosphere, Ocean, atmosphere, and its features are as follows:

Process flexibility, suitable for important large and difficult to maintain long-term protection of steel structures, construction site

Zinc or aluminum coating and spray coating closed, can greatly extend the service life of the coating, theory and practical application of the results, spray coatings of zinc or aluminum is the best coating the bottom. Metal spray coating with anticorrosive paint coating composite coating protection of life is metal spray coating and coating protective layer between the longer life expectancy and, for single coating protective layer of life a few times.

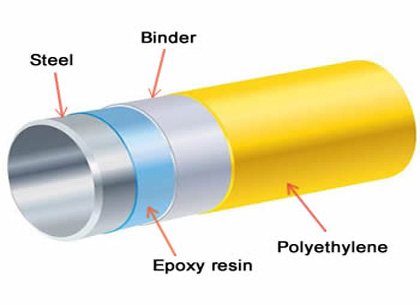

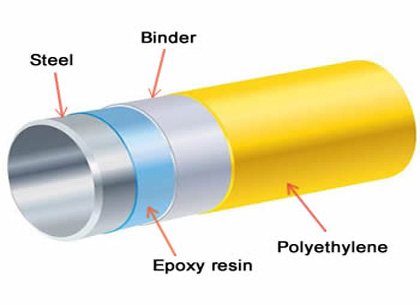

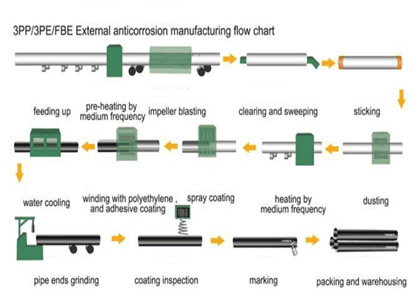

2PE/3PE coated steel pipe(executive standard : GB-T23257-2009)

Buried steel pipes with 2PE/3PE coating are used for the transmission of water , oil , gas and other media , the working temperature is 50℃---70℃ , it has good performance of anti-corrosive , low water-absorption rate , high mechanical strength.

External PE coated steel pipe (executive standard : DIN30670-1991)

Buried steel pipes with 2PE/3PE coating are used for the transmission of water , oil , gas and other media , the working temperature is 50℃---70℃ , it has good performance of anti-corrosive , low water-absorption rate , high mechanical strength.

External dual-layer fusion bonded epoxy powder coating(executive standard : Q/cnpc38-2002)

Steel pipes with external dual-layer fusion bonded epoxy powder coating are used for the transmission of water , oil , gas and other media , the working temperature is 30℃---100℃ , the coating is easy to paint and no pollution. It has good performance of anti-impact , bending and high temperature-resistance.It is widely used in domestic and interational.

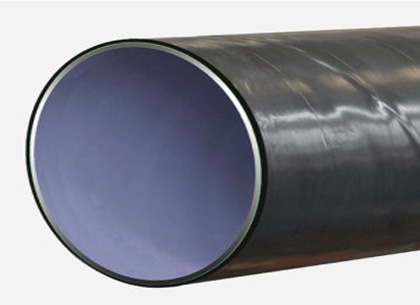

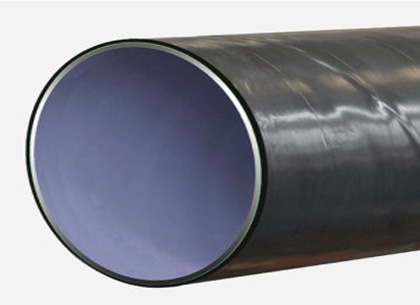

Fusion bonded epoxy powder coating(executive standard : SY/TO442-2010)

Steel pipes with internal fusion bonded epoxy poeder coating are used in transmission of water , natural gas and other media , the working temperature is 30℃---100℃ ,it can decrease the re-pollution during transmission , and prolong the lifetime of steel pipeline.

Coal tar epoxy coated steel pipe(executive standard : SY/TO447-96)

Steel pipes with coaltar epoxy coating are used in transmission of water , oil, natural gas and other media , the temperature of transmitted media can not exceed 110℃ , it has function of anti-corrosive.

Corrosion protection is the protection of steel quality, 3PE processing of steel pipe, long service life, good effect. The technology used can be determined according to the needs.

GET IN TOUCH

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!

Product Brochures,Instant FREEDownload

We Respect Your Email Privacy, We Hate Spam As Much As You Do!